Fly Ash Brick Manufacturing Machine – A Revolution in New Age Construction

Fly Ash Brick Manufacturing Machine – A Revolution in New Age Construction

Introduction

In India’s rapidly growing construction industry, cost efficiency and sustainability are no longer options – they are inevitable. While the government and public sector are both promoting green building materials, the fly ash brick is proving to be a game-changer alternative to the conventional clay brick.

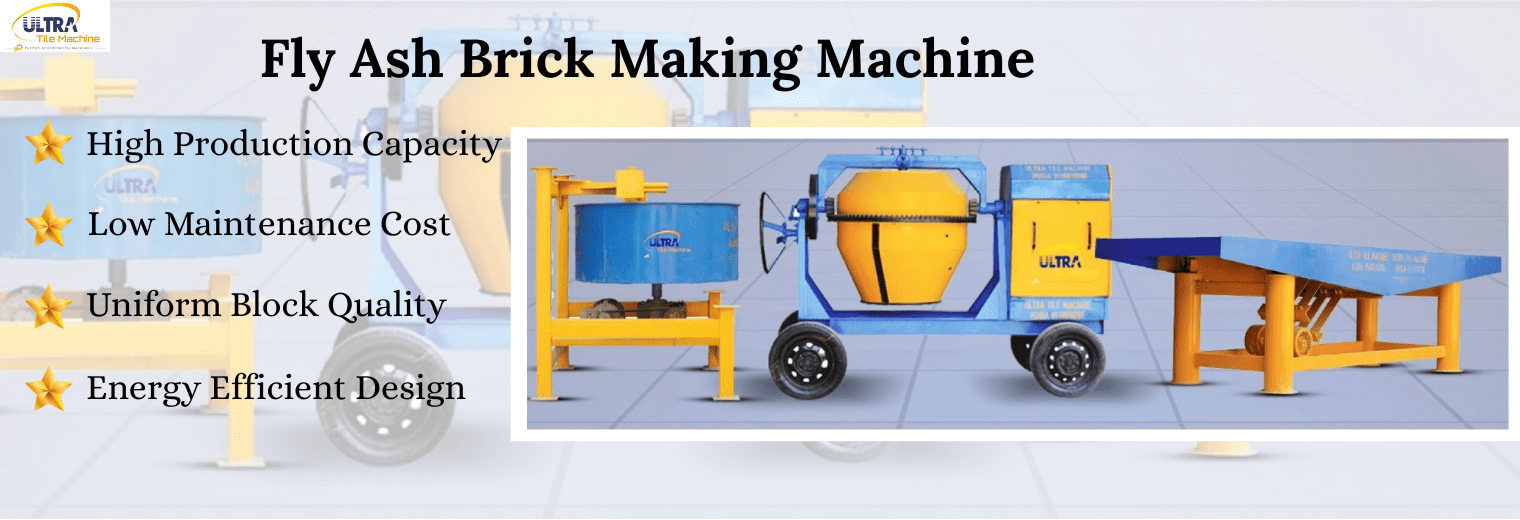

The hub of this change is the Fly Ash Brick Making Machine, an advanced solution to produce top-notch, uniform, and durable bricks in bulk. Ultra Tile Machine, a leading manufacturer and exporter in India, offers state-of-art machinery that maximizes efficiency, profitability, and sustainability for builders, contractors, and entrepreneurs.

What is Fly Ash Brick Making Machine?

A fly ash brick machine is a device employed to produce bricks from a combination of:

- Fly Ash (thermal power station waste product)

- Cement

- Sand

- Stone Dust

- Lime (optional in some models)

These raw materials undergo high hydraulic pressure and vibration to produce strong, eco-friendly, and uniform bricks.

👉 Available in manual, semi-automatic, and automatic forms depending on production size and cost.

Why Use Fly Ash Bricks? (Advantages Over Traditional Clay Bricks)

- ✅ Eco-Friendly – Utilizes industrial waste product (fly ash), reducing pollution and saving arable land.

- ✅ High Strength & Durability – Same shape with compressive strength of 7.5–12 MPa, higher than clay bricks.

- ✅ Cost-effective – Requires less mortar and plaster.

- ✅ Fire & Water Resistant – Excellent thermal insulation and low water uptake.

- ✅ Even Finish – Uniform size ensures faster construction and less plastering cost.

- ✅ Government Support – Subsidies and incentives for green building products.

👉 Because of these advantages, fly ash bricks are widely used in residential complexes, commercial projects, highways, industries, and govt. housing schemes.

Features of Ultra Tile Machine – Fly Ash Brick Making Machines

- High Output Capacity – 2,000 to 10,000 bricks per shift

- Hydraulic Compaction Technology – Strong & crack-free bricks

- Low Power Consumption – Energy efficient motors

- Durable Steel Structure – Long service life

- Automation Options – Semi & Fully Automatic available

- User-Friendly Design – Easy operation & maintenance

- Customizable Molds – Different block & brick sizes

Technical Specifications (Generic Models)

- Production: 2,000 to 10,000 bricks/shift

- Automation: Semi-Automatic / Fully Automatic

- Standard Brick Size: 230 x 110 x 75 mm

- Hydraulic Pressure: 150–200 tons

- Raw Materials: Fly Ash, Cement, Sand, Stone Dust

- Warranty: 1 Year (with after-sales support)

Applications of Fly Ash Bricks

- ✅ Residential Housing Projects

- ✅ Commercial Complexes & Shopping Malls

- ✅ Government Housing Schemes (PMAY etc.)

- ✅ Industrial Buildings & Factories

- ✅ Pavements, Boundary Walls & Landscaping

- ✅ Schools, Hospitals & Urban Infrastructure

Cost & Profitability of Fly Ash Brick Making Machine

Initial Investment: ₹8 Lakhs – ₹30 Lakhs (depends on type & automation)

Production: 2,000 – 10,000 bricks per shift

Selling Price: ₹5 – ₹7 per brick

Profit Margin: High ROI due to low-cost raw materials (fly ash is free/subsidized) + huge demand

👉 With govt. mandates on eco-friendly construction, the fly ash brick industry is highly profitable.

Why Choose Ultra Tile Machine?

- ✅ ISO-Certified Quality Standards

- ✅ Advanced Hydraulic & Vibration Technology

- ✅ Long-lasting, Low Maintenance Machines

- ✅ Free One-Year Warranty + After-Sales Service

- ✅ Trusted by Builders, Contractors & Govt. Agencies

- ✅ Pan-India & International Export Network

👉 Not just equipment – we provide a complete business solution for your success in the fly ash brick industry.

Frequently Asked Questions (FAQs)

Q1. What is the price of a fly ash brick manufacturing machine in India?

➡ ₹8 Lakhs to ₹30 Lakhs, depending on capacity & automation.

Q2. How many bricks can it produce in a day?

➡ 2,000 – 10,000 bricks per shift (model-based).

Q3. Do fly ash brick plants get government subsidy?

➡ Yes, as part of green building promotion policies.

Q4. What raw materials are required?

➡ Fly Ash, Cement, Sand, Stone Dust (lime optional).

Q5. Are fly ash bricks better than clay bricks?

➡ Absolutely! They are stronger, eco-friendly, durable, and cost-effective.

Conclusion

The future of construction lies in eco-friendly and cost-effective materials, and fly ash bricks are leading the way. Investing in a Fly Ash Brick Making Machine is not just about brick production – it’s about building a sustainable and profitable business.

Ultra Tile Machine ensures top-quality machinery, unmatched support, and reliable service to help entrepreneurs, contractors, and builders succeed in this booming industry.

👉 If you’re planning to set up a Fly Ash Brick Plant or upgrade your existing facility, contact Ultra Tile Machine today for the best prices and high-performance machines.